Software package KSE CK-Pro

>> KSE CK-Pro brochure

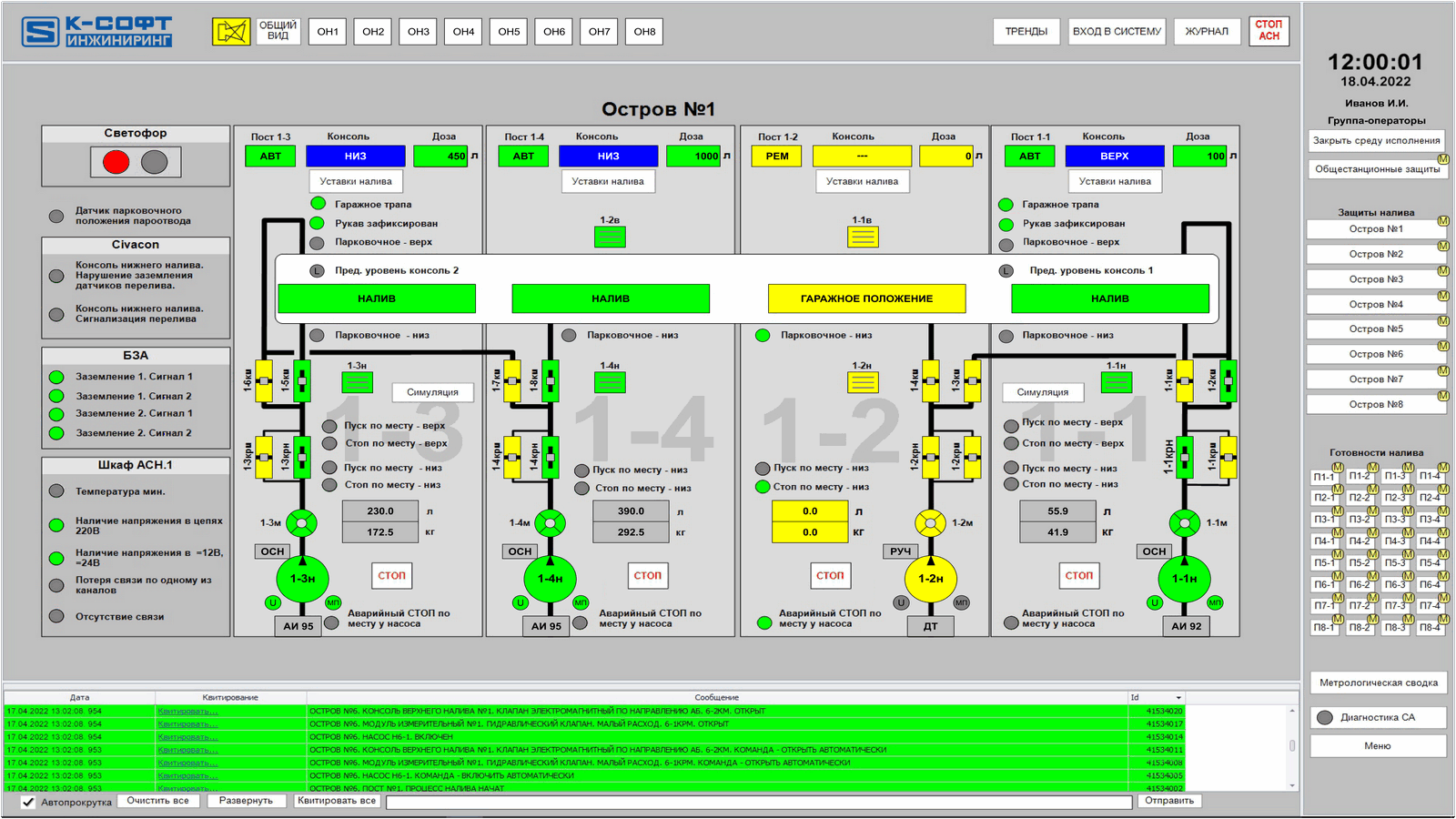

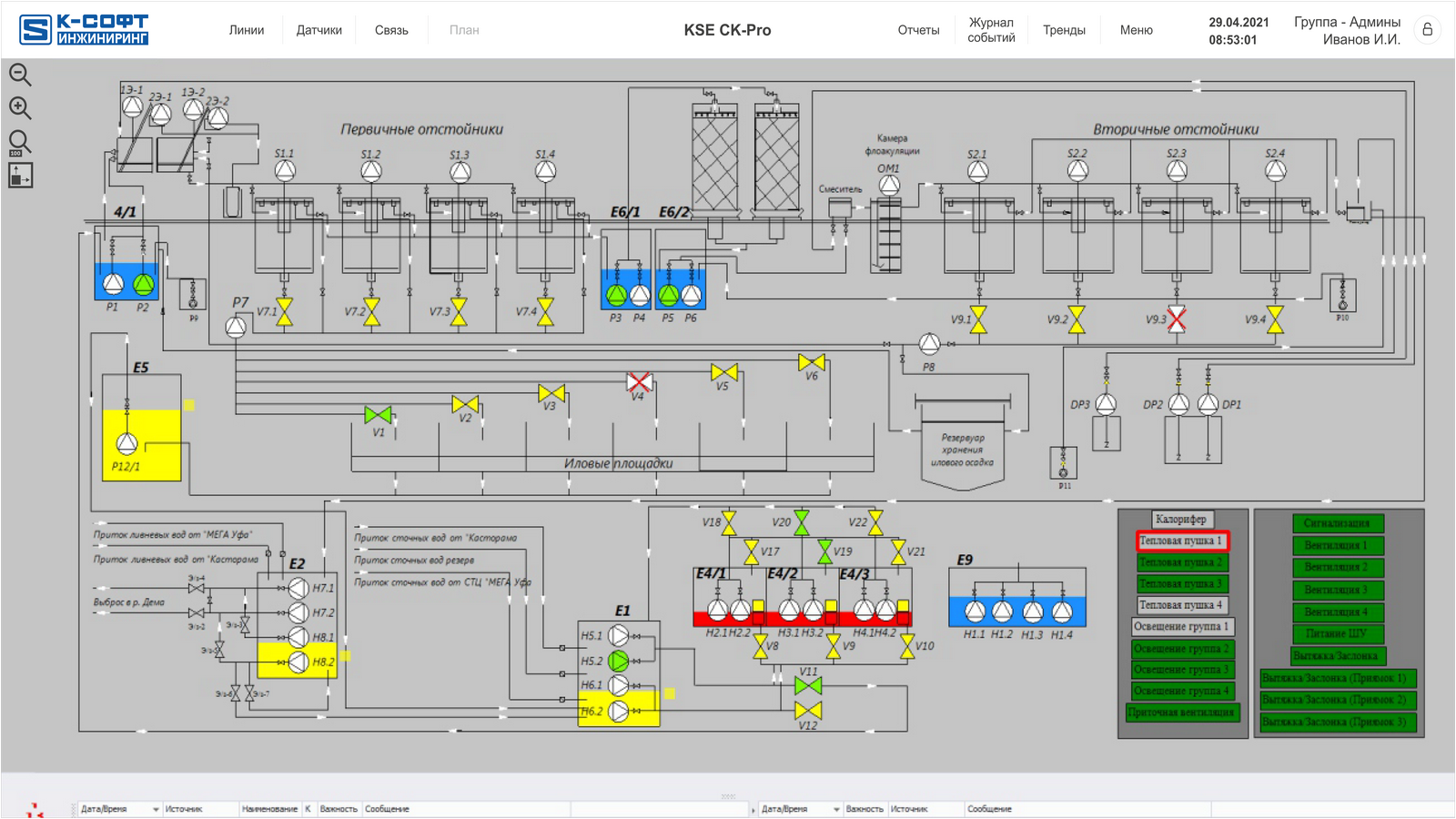

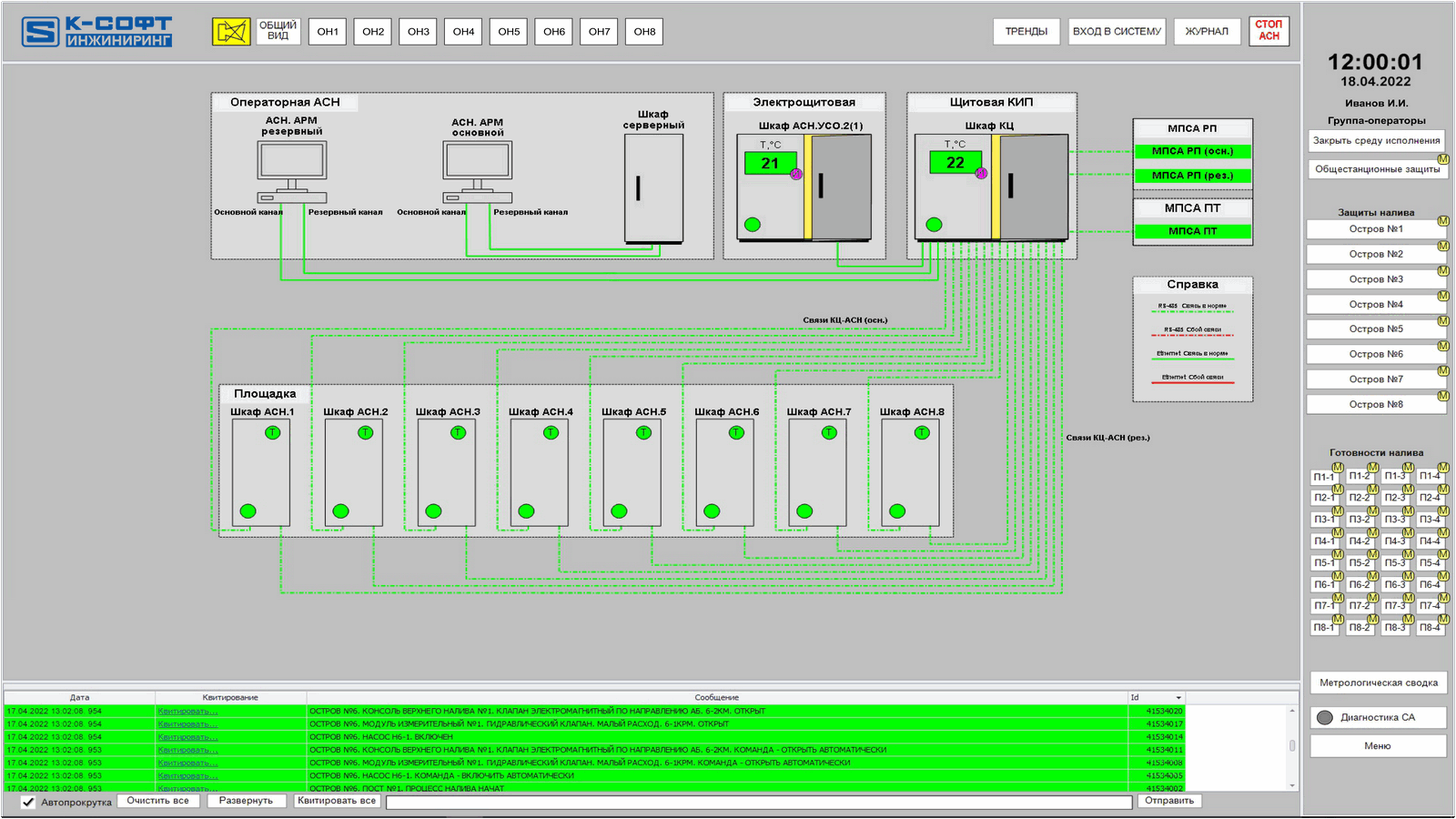

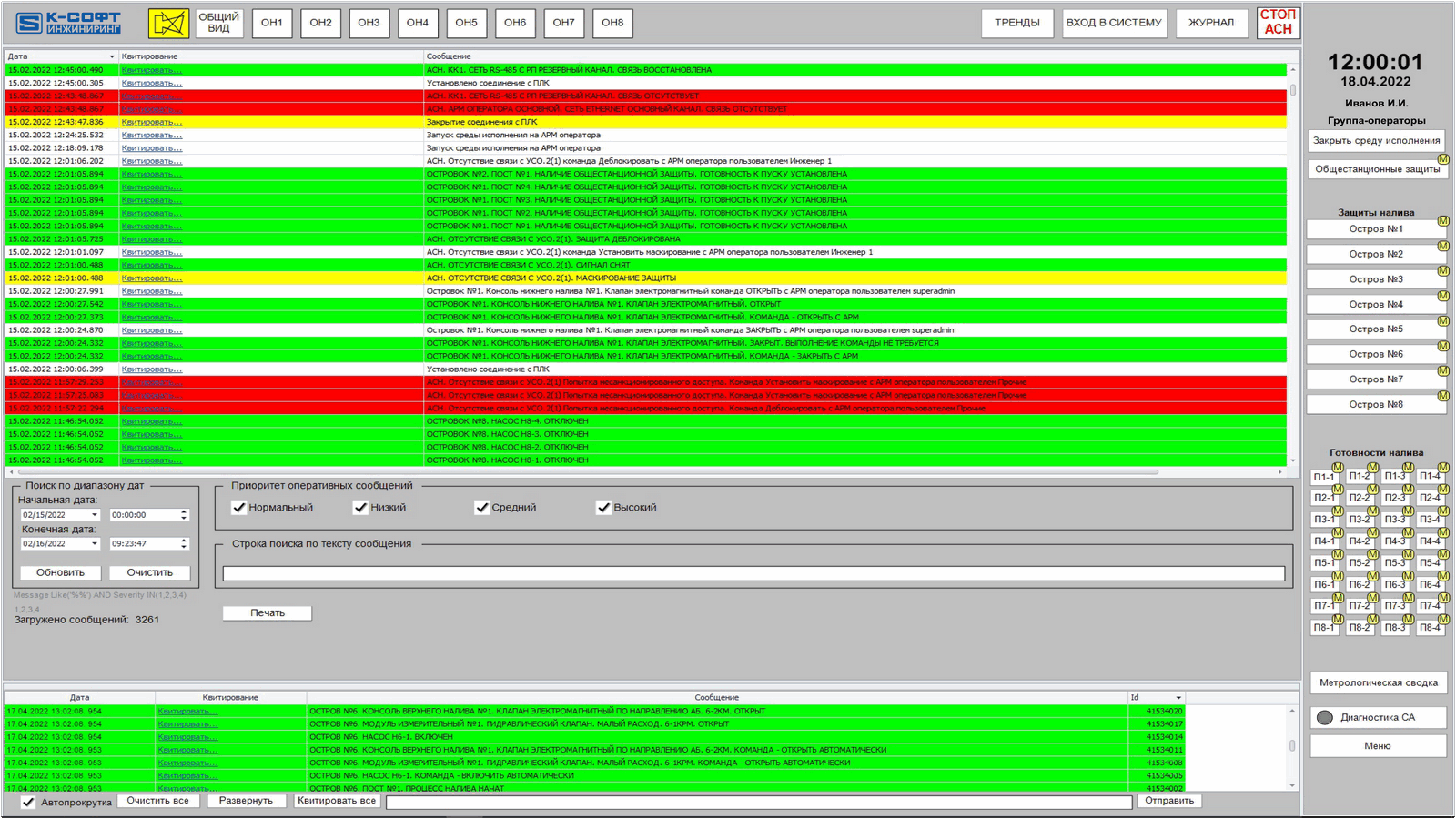

Universal software package for automation of industrial enterprises, designed for monitoring and intelligent control of technological processes:

- Oil and gas treatment

- Oil and gas transportation

- Oil and gas processing

- Waste water treatment

- Chemical industry

>> KSE CK-Pro brochure