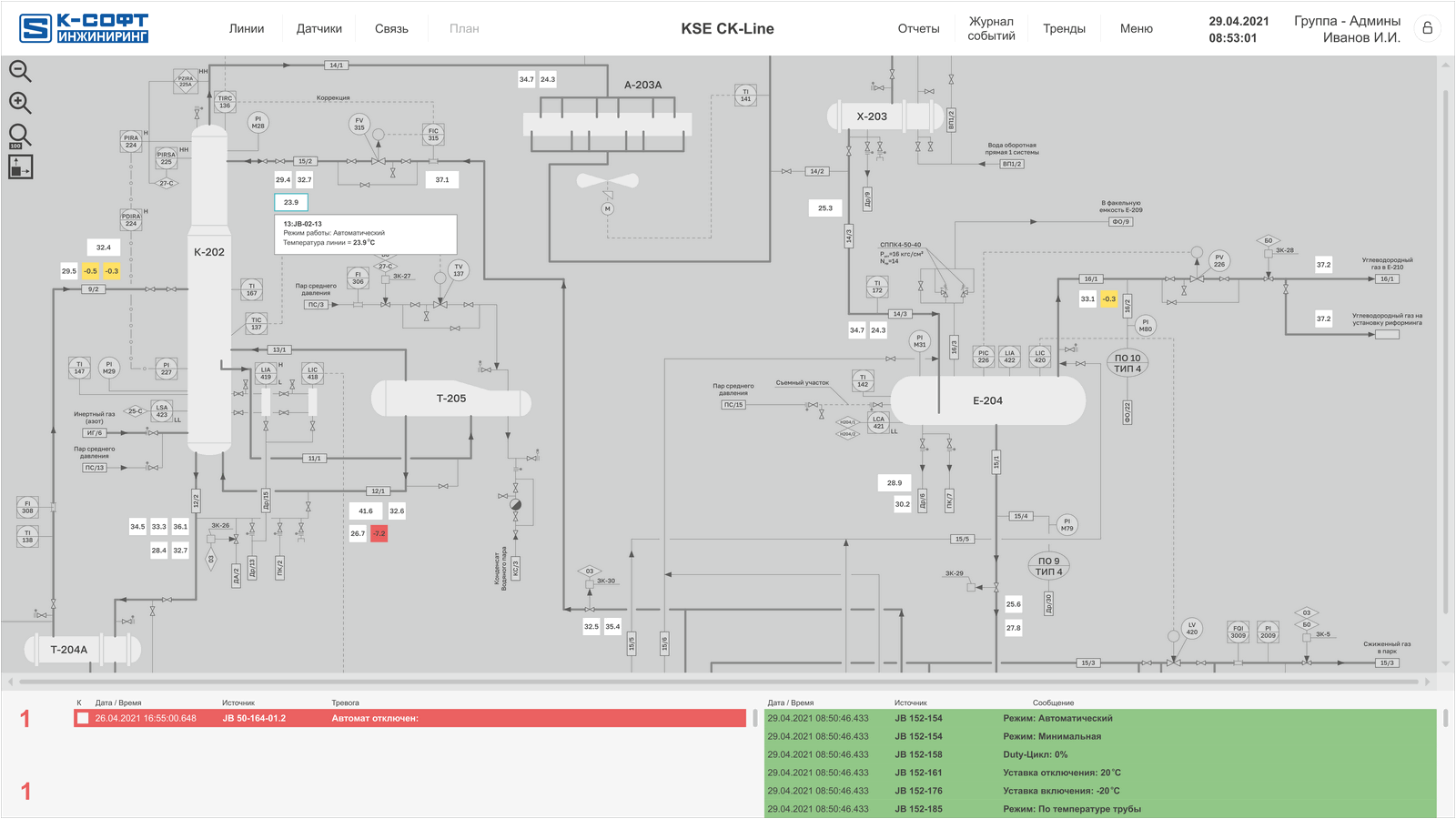

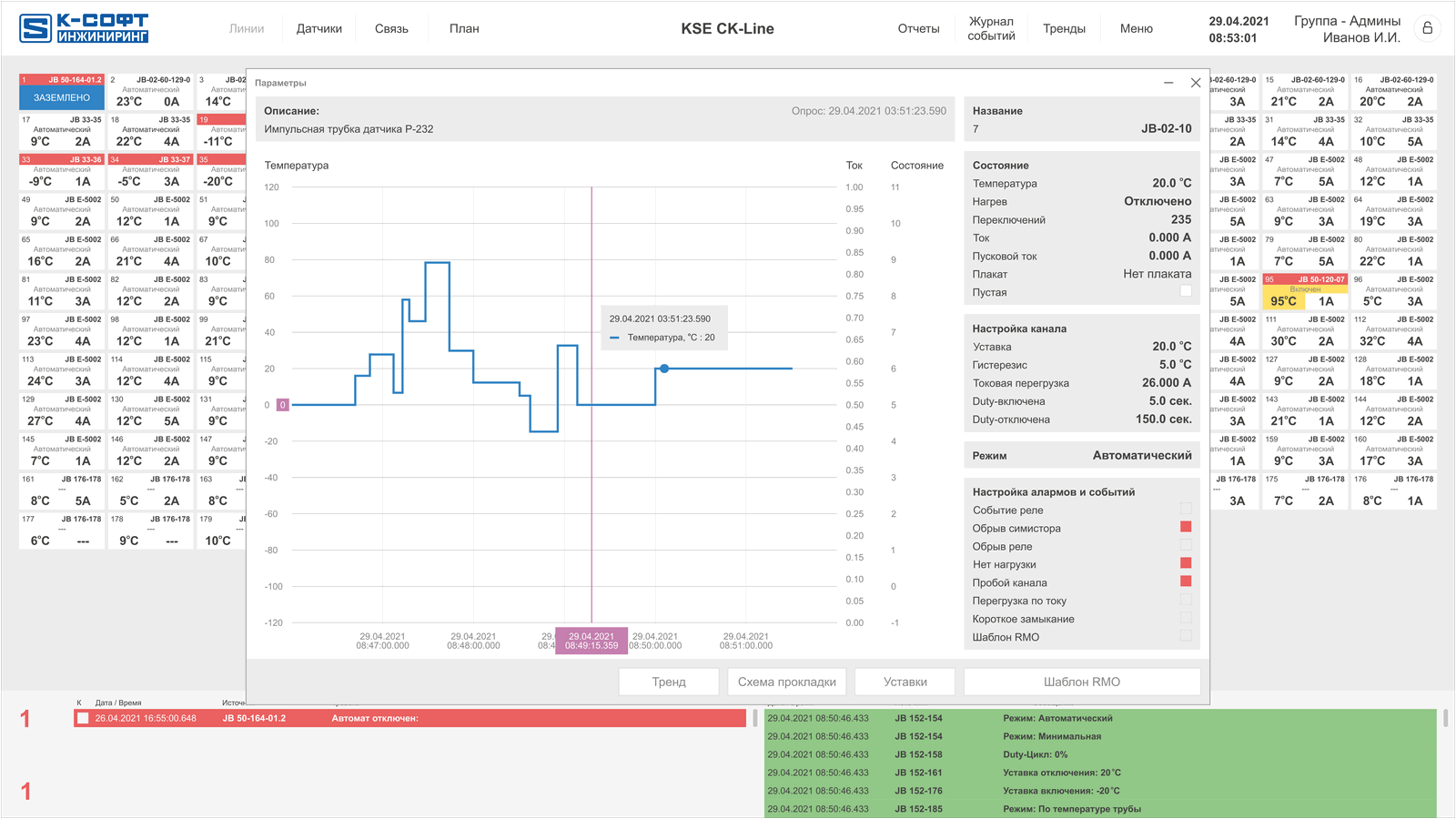

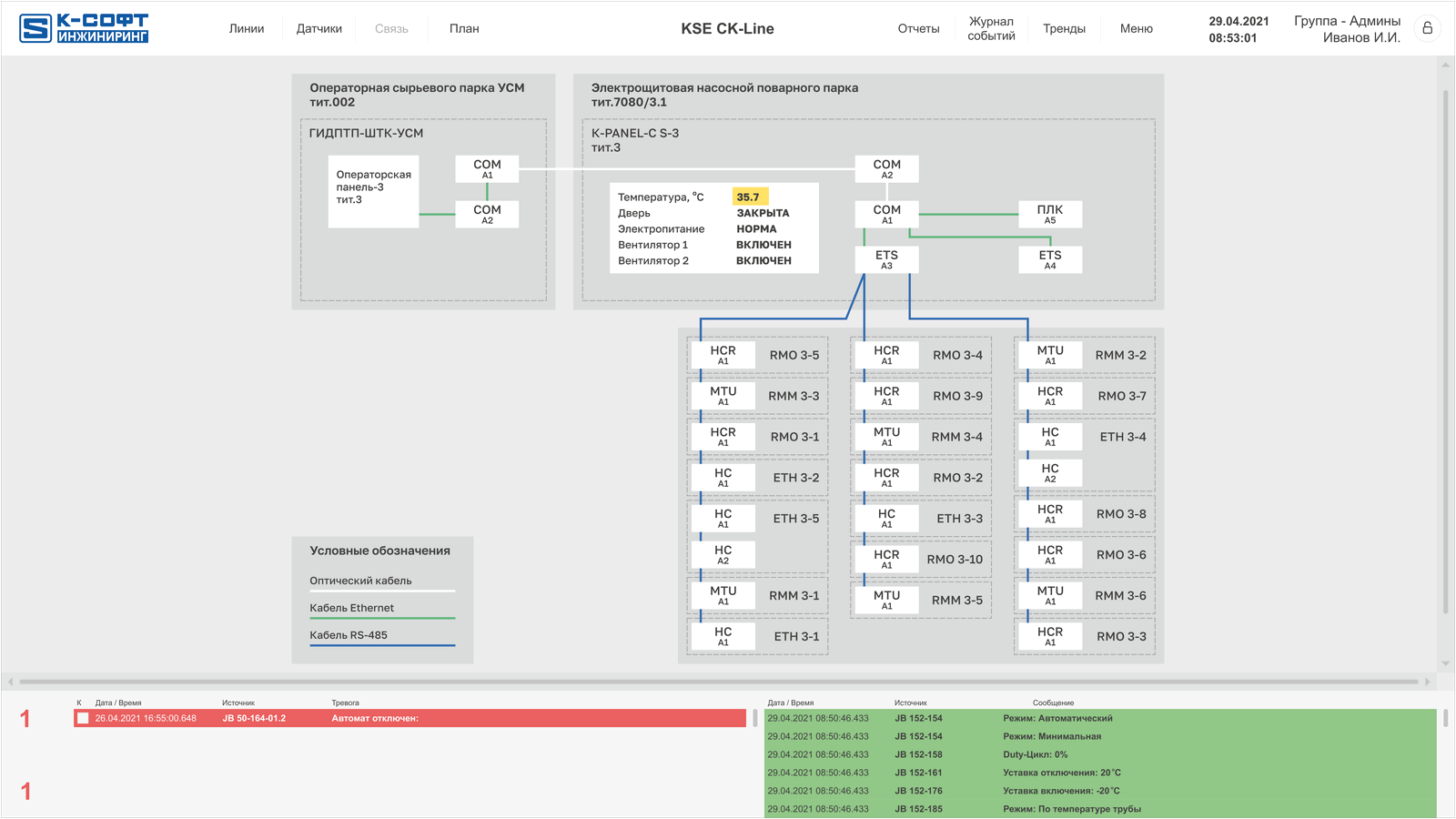

Software package KSE CK-Line

>> KSE CK-Line brochure

Specialized software package for electrical heating automation, designed for monitoring and intelligent control of heating of various objects:

- Pipelines

- Reservoirs

- Impulse lines

- I&C cabinets

- Floors of open pump stations

- Roofs and gutters of buildings

>> KSE CK-Line brochure